THE SCUBA CYLINDER

Scuba cylinders (tanks) come in a variety of sizes. They range in size from a little over 9" tall by 2" across to over 22" tall by 8" in diameter. Smaller tanks are usually for an emergency backup. You cannot always tell from the size of the tank how much air it holds. Sometimes smaller tanks contain more air than larger ones.

How do you find out if a tank is full? It is necessary to find out what the maximum pressure a tank can hold, and then put a gauge on the tank to see what pressure it actually has. The maximum pressure is stamped near the top of the tank. On the neck of the scuba tank there is a number that will be in the thousands such as 1800, 2150, 2250, 2475, 3000, 3300, 3500, 4500, etc. The number might be preceded by a code such as 3AA, 3AL, E9498, etc. That number is the maximum pressure rating for that cylinder. Once that is known, a gauge can be put on the valve to see if the tank is full. Also, there is a gauge attached to the regulator supplying the air for scuba diving with allowing you to monitor the air pressure under water.

There are two major types of scuba cylinders. Some are made of steel and some are aluminum. There are advantages and disadvantages of each. If you had 2 cylinders of equal outside dimensions, one was steel and the other was aluminum, and they had equal maximum pressure ratings, the steel tank would hold more air. Steel is a much stronger metal than the aluminum alloy used to make tanks. So the steel tank's walls are less than 1/2 the thickness of the other. The interior volume of the steel tank is greater than the aluminum tank. A disadvantage to steel is that it may rust. Iron oxide rust flakes off, and then more rusting takes place in the same spot weakening the wall of the steel cylinder. When aluminum "rusts" it forms aluminum oxide. Aluminum oxide stays in place and protects the metal underneath. However, there should be no rust in any scuba tank if the air that is used to fill it is properly dried, and the tank has not been emptied with the valve left open.

The amount of air in a scuba cylinder is usually measured in cubic feet. The most popular of these is the 80 cubic foot, 3000 psi, aluminum cylinder. The quantity is rounded off and the tank really contains 77 cubic feet (cf) of air when it is filled to 3000 psi. (For your information, the tank has an actual interior volume of 0.4 cf..) The small Spare Air (R) contains 2.7 cf at a similar pressure. Typical pony bottles contain 6, 13, 19, or 30 cf. The "standard" 2250 psi steel tank contains 71.2 cf when it is filled to 10% above the 2250, or 2475 psi. That is only permitted if the tank has a "+" stamped into the metal after the hydro symbol. Without the "+" the tank should not be filled above 2250 psi. That steel tank now would contain only 64.7 cf at its rated 2250 psi.

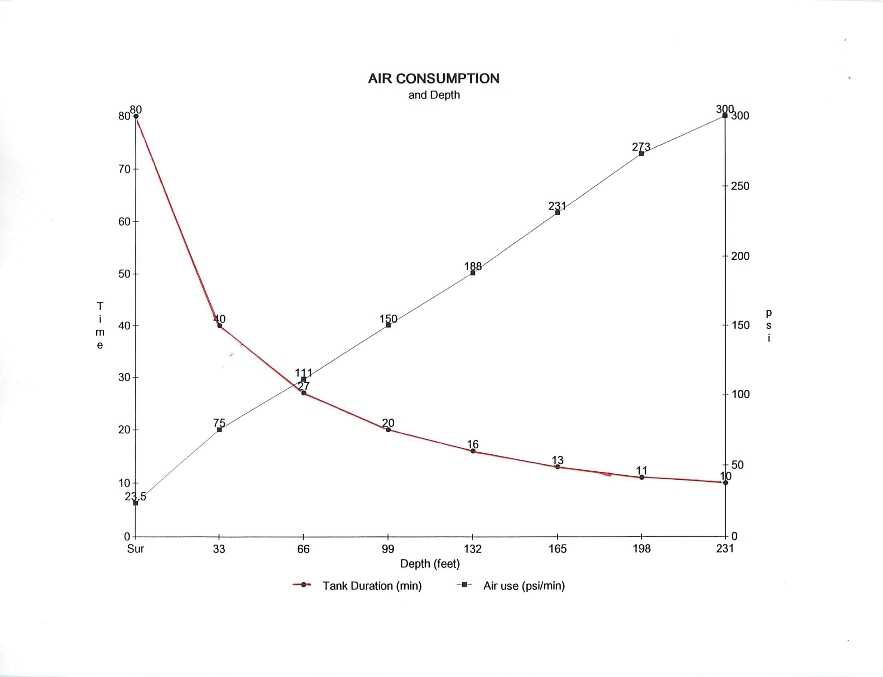

The above chart was from Lynn Laymon's article, A Tank is a Tank, Dive Training Magazine, November 2004

This discussion brings up the question of how long can a diver stay under water before the air runs out. First of all, divers should not stay down until the air runs out. That is quite unsafe and also invites contamination if the tank valve is open and the surrounding air enters it after the regulator is removed. It is best to reach the surface with no less than 300 psi in the tank. People breathe somewhat less than a cubic foot of air per minute at the surface. This is a very rough estimate because it depends on several factors:

The author has had a tank last only 20 minutes while working in a reservoir laying a community water pipe in Harrison, NY in the winter. Due to cold, and a heavy work load, the tanks were emptied rapidly even through the water was only 25 feet deep. Contrast that to having a tank last almost 2 hours while examining a reef in the Caribbean (83 degrees) in 7-10 feet of water.

The above graph shows how long an 80 cu ft tank would last at various depths (red line). If it lasted 80 minutes at the surface it would last 40 minutes at 33'. The black line shows the increased psi/minute that leaves the tank at different depths.

Air has weight. The air in an 80 cubic foot tank weighs about 6 pounds. As the air is breathed out the tank gets lighter. That changes a diver's buoyancy as the dive progresses. For example, if you threw an 80 cf aluminum cylinder in the ocean its negative buoyancy is 2.5 pounds. (It sinks with a force of 2.5 lbs.) When that tank is empty it floats with a force of 3.5 pounds. During the dive there is a change of approximately 6 pounds in a diver's buoyancy! Toward the end of the dive the tank exerts quite a bit of floating force on the diver. It is just as if the diver removed 6 pounds of weight from the weight belt and discarded it! An aluminum 80 has a weight when full slightly more than 33 pounds, and a volume of 0.5 cu ft. That puts the full tank's density at (33 pounds/0.5 cu ft) 66 pounds per cu ft. Since seawater is 64 pounds per cubic foot, the tank will sink when full with a force of 2 pounds.

The following is a chart of various tanks, the amount of air in them, and their buoyancy in fresh and salt water:

The submersible pressure gauge (spg) attached to the first stage of the regulator tells the diver the air pressure in the tank during the dive. It is important to monitor it frequently to avoid running low on air. Be sure to leave enough air in the tank to safely surface with at least 300 psi in the tank when the dive is terminated. Novice divers need to concentrate on checking the spg. Sometimes it is not done because there are so many new experiences overwhelming the senses.

Air for breathing at depth must be less polluted than what is found at the surface. If the air contains some pollution it will be twice as polluted at 33'. Poisons in the air are magnified as the diver descends. One way to tell if you are breathing pure air is to smell it. By opening the tank valve slightly (and carefully) and smelling the air, your nose should not be able to detect any odor. If even the slightest odor exists, such as an oily smell, it is best to not dive with that tank until it is dumped, cleaned, and refilled from a good air source. Scuba diving requires Grade E air. Grade E air, according to the Compressed Gas Association (CGA), has the following maximum limitations:

In another chapter we will be discussing Nitrox for breathing underwater. For Nitrox the air must be less contaminated than what is allowed for Grade E air. The CO level must not exceed 2 ppm, the oil and particulate matter must be less than 0.1 mg/cubic meter, and the carbon dioxide level must be less than 500 ppm.

Compressors used for filling scuba tanks must be designed for that purpose. They are expensive! They are not like those used to fill tires at your local gasoline station. The main compressor at Deep-Six costs over $15,000 new. The air going into it comes from the outside the building. No smoke from vehicle exhaust, wood stoves, lawn mowers, etc. should be allowed to enter the intake. The air is dust-filtered and then compressed in 4 stages. Water and oil are drawn out of the air in the stages. The air then passes through filters that remove carbon dioxide, carbon monoxide, remaining water, oil vapors, and other contaminates. The filter is electronically monitored to be sure it is functioning. If the filter gets to a point it is not doing the maximum job the compressor will not start. Finally the air enters the tank in a super-clean and super-dry state. This results in dry throats during dives and no odor when the air is smelled.

If you were to take an aerosol container, such as a hair spray, and discharge the contents rapidly, a cooling effect will be noticed. As gases decompress (expand) they cool. The opposite is true as well. If you compress a gas it will get hotter. This is according to Charles Law. If an 80 cf tank is filled too quickly it will get hot to the touch. If you were to totally open the valve of a filled tank, frost would form on the valve even on a hot day. Jacques Charles stated that if you compress a gas it will get hot, and if you decompress a gas it will get cold. If you take a scuba cylinder to a dive shop and they fill it too fast you will pay for air you did not get. The pressure may indicate the tank is full. When the tank cools down the pressure will drop significantly. There will be more cooling and pressure loss when in the water. The loss could lower the tank's pressure from 3000 psi to less than 2500 psi! For every degree of change there is a change of about 5 psi in the tank's pressure.

Although it should never happen, running out of air is not what you might think. The end point is not abrupt. It's not like you exhale and then find there is no air to inhale. When the pressure is low the air becomes increasingly harder to draw out of the tank. The breathing gets harder and harder until there is a long and tedious breath at the end. From the point of first realizing there is a restriction, until the air is hard to draw in, may last fifteen seconds or more. The time is not definite. It's actually a good experience to draw a tank down to zero as long as you are expecting to do it, and it is done in the shallow water of a swimming pool. Remember: There will be no air to add to the BCD when the tank is empty so this experience should not be done with an over-weighted diver or in open water. Again, an empty tank can become contaminated if the valve is left open after the regulator is removed.

There are other important markings on the neck of a tank. Of major consideration is the hydrostatic test date. Looking again at the top of a tank, there will be a place that shows a month, followed by a test station ID, followed by a year. It will look something like: 6 X 98. The X represents the federal identification number. There may be several dates if the tank has been tested in other 5-year intervals. The latest date indicates the last time the tank was tested to be sure the metal is able to withstand the extreme pressure it receives. Scuba tanks must be tested every 5 years. If the last hydrostatic test date is more than 5 years old, the tank will not (and should not) be filled by most dive shops. This policy is for the safety of the shop and the owner of the tank. Also, there is a heavy federal fine for transporting a pressurized cylinder that does not have a current hydro date.

When a cylinder is filled it expands due to the pressure inside. When the air is breathed out of the tank it contracts. The metal of the tank flexes as it is being used. If you take a piece of metal and repeatedly bend it back and forth it will eventually break because the metal gets fatigued. Although aluminum scuba tanks can withstand over 100,000 fills it is important to be sure the metal has not becomed fatigued or brittle. That is why the federal government requires hydrostatic testing of high-pressure cylinders every 5 years. Essentially a scuba tank is subjected to 5/3 of the pressure rating found on the neck so the expansion and contraction may be measured exactly. A 3000 psi cylinder would be hydrostatically tested to a pressure of 5000 psi.

The owner of Deep-Six has done hydrostatic testing for many cylinders. There is an entire part of the Web Page devoted to how this procedure is done. Please visit the Hydrostatic Testing section on the Deep-Six Home Page to gain full insight into what is done to insure that a tank is safe to fill with high-pressure gas.

Because tanks contract when the air pressure drops, if the BCD was not put on the tank tightly, the tank may come out and trail behind the diver. Sometimes it will not come out until the diver leaves the water and the tank gets heavy. It presents a problem that can be avoided by simply insuring the tightness prior to the dive. Wetting nylon BC tank straps has little affect on the tightness achieved. All it may do is to lubricate the strap so it slips more easily through the buckle.

In addition to insuring the integrity of the metal every 5 years, it is important to have a tank visually inspected by trained personnel every year. This is called the Visual Tank Inspection (VTI). During a VTI the tank is opened and the interior is carefully examined for contamination, corrosion, neck cracks, intact threads, and damage. The area where the treads join the body of the tank must be checked for cracks if the tank is aluminum. The exterior is examined for bows, bulges, corrosion, dents, and gouges. If the tank is free from damage a decal is applied that states the inspection was done and the tank is in satisfactory condition. The decal is dated by month and year and expires after one year.

Neck cracks (Sustained Load Cracking - SLC), as explained at the end of this page, is a problem with certain tanks that were made of the 6351 aluminum alloy. Many of these cracks are not able to be seen with the naked, and especially the untrained eye. They are detectable with a sophisticated instrument called the VisualPlus 3. If you tap the next link you will be able to see some interesting pictures and data on tanks with and without neck cracks.

A few years ago a person decided to add a chrome finish to an aluminum tank. To do this required heating the tank to 400+ degrees. After the process was completed the tank exploded while it was being filled! This unfortunate incident led to the discovery the aluminum alloy in scuba tanks becomes more brittle and less flexible if it is heated to above 350 degrees. Aluminum tanks that have been subjected to extreme heat (less than 350 degrees), such as a house fire, must be hydrostatically tested prior to use. In cases where the tank has been heated to over 350 degrees they must be condemned and rendered usless so they will never be pressurized again.

That brings up another point: Charle's law relates heat to pressure. If there was a house fire and scuba tanks were in it, would there be an immediate threat to the firefighters? When scuba tanks are heated the pressure rises. Would the tanks explode if they were full? The answer is "No." In the valve of the tank there is a safety plug that is designed to split when the pressure climbs near the hydrostatic test pressure. If a 3000 psi tank were heated to the point the pressure climbed to 5000 psi (about 400 degrees F) the safety plug would split and the air would quickly leave the tank. Contrary to myth, there is no danger of tanks getting that hot in the trunk or in the interior of a car.

At the bottom of the tank there is usually found a boot. It is made out of plastic or rubber. It is there to keep the tank from getting scratched and gouged. Some tanks have round bottoms. Tank boots conform to the round bottom on the inside but have flat bottoms on the exterior. This will allow a round-bottom tank to stand up. The boot should be self-draining. It should allow water to run out of it when the tank is on land and the salt water is rinsed off. Small grooves around the inside edge of the boot do this. If the boot has a flat and smooth interior it will keep water permanently against the tank's metal resulting in corrosion, and with a steel tank, rust..

Rust caused by non-draining boot

When tanks are transported in a vehicle the bottom of the tank should be facing toward the front. The biggest danger in accidents is a front-end collision. If that were to happen the bottom of the tank, rather than the valve, would be subjected to the force of the impact. If the vehicle is too small to allow the tank to be placed in that position then it would be best to place them sideways. No matter what, the tanks must be packaged so they cannot roll or shift around.

Many instructors insist on never letting a tank stand upright without some support. This is especially true if the tank could fall over with the valve hitting a rock, chair, etc. It's not that dangerous if the floor is flat and there is nothing sticking up. But, never allow a tank to be placed on a high object such as a chair, bench, table, etc. unless it is supported at all times. Don't even walk away for 1 second with a tank off the ground! This author has seen, on more than one occasion, a tank fall off a bench at a dive site or on a boat, land on the regulator, bend the yolk that attaches the regulator to the tank, causing the air come screaming out through the leak that developed. One time the escaping air blew a trench in the shale on the ground that was at least 10" deep before the valve could be closed! Needless to say, the cost to repair the regulator was extensive.

What about the question, "How long is the air in a tank good for?" As long as the air is not contaminated, especially with water, it should last indefinitely. If a steel tank had been filled from a compressor that did not remove water from the air, during storage the moisture may react with the steel to create rust. Rust is iron oxide. The iron comes from the tank. The oxide comes from the oxygen in the air. The oxygen is used to form the rust, reducing the amount needed for sustaining the diver's life. Taken to an extreme case, the diver could dive breathing almost pure nitrogen. There would be no real warning of the appending asphyxiation because there would be no carbon dioxide excess indicating a need to breathe.

The LUXFER 6351 Aluminum Tanks and Sustained Load Cracking (all in red):

The Luxfer 6351 aluminum alloy was used in tanks that predate 1989. In a very few of those tanks there has been found sustained-load cracking in and around the neck and threads of the tank. Out of 30,000,000 6351 tanks, 17 ruptured. That is 0.00006%! Out of 6,100,000 6351 tanks, 0.37% were found to have sustained-load cracking. It takes an average of approximately 6 years for a tank with sustained-load cracking to begin to leak. The tanks that have developed sustained-load cracking are ones that have been abused, damaged, or over-filled.

RIVERSIDE, Calif. (December 9, 2002)-Luxfer Gas Cylinders has announced a new scuba tank trade-in program to enable owners of older Luxfer scuba tanks manufactured in the U.S. from 6351 aluminum alloy to trade in their tanks and receive a $50 credit for each tank toward the purchase of new scuba tanks made from Luxfer's proven, proprietary 6061 alloy. Luxfer implemented the simple four-step program outlined below on January 1, 2003. The program ended on December 31, 2003. That was a limited one-year offer.

To determine whether your Luxfer scuba tank is made from 6351 aluminum alloy, check the original hydrostatic test date (the earliest date) stamped on the crown. (Look for a month/year combination, such as 3/75.) If the stamped year is 1972 through 1987, the tank is made from 6351 alloy. A limited number of Luxfer scuba tanks were also made from 6351 alloy during the first half of 1988. If you have a 1988 tank with an original hydrostatic test date of 6/88 or earlier, Luxfer assumed that it was a 6351-alloy tank and issued an RG number. Tanks with an original hydrostatic test date of 7/88 or later are made from 6061 alloy and were not eligible for the trade-in program.

Why did Luxfer sponsor this program? Is something wrong with these older tanks made from 6351 aluminum alloy?

As long as these older tanks are properly inspected and requalified as required by U.S. Department of Transportation (DOT) and Luxfer, you may continue to use them. DOT requires that the tanks be requalified every 5 years. In addition, Luxfer requires that the tanks receive a visual inspection by a properly trained inspector and an eddy-current test at least every 2½ years. (Please note as well that an annual visual inspection is a standard practice in the U.S. scuba industry, and Luxfer endorses this practice for all scuba tanks, not just those made from 6351 alloy.)

Luxfer sponsored this trade-in program for commercial purposes. The program operates much like a coupon for a commercial product. The intent is to increase demand and brand awareness in the marketplace by offering a trade-in discount on a new Luxfer scuba tank. This trade-in program also enables divers to upgrade tanks made from older- technology aluminum alloy to newer tanks made from Luxfer's proprietary 6061 aluminum alloy.

How do I know if it is a Luxfer tank?

You can tell by several markings on the tank. The serial number will begin with a prefix. (For example, in the case of an 80-cubic-foot tank, the prefix will be a P.) The serial number line should also contain Luxfer's name.

TANK SIZE PREFIX TANK SIZE PREFIX TANK SIZE PREFIX

S030 UU S063 PP S808 UV

S040 LS S072 Y S092 US

S050 R S080 P S100 UT

The US Government has determined that no recall is warranted for the Luxfer 6351 tanks. No scuba cylinders have been recalled! The Luxfer 6351 tanks are not to be condemned unless they show evidence warranting such. There is no reason for a dive shop to refuse to fill them. There is the potential to wrongly convince a customer they should be replacing the cylinder with a new one.

Luxfer scuba cylinders were manufactured from 6351 aluminum alloy during the following periods:

· United States : 1972 through mid-1988

· England : 1967 through 1995

· Australia : 1975 through 1990

Luxfer requires that every Luxfer 6351-alloy all-aluminum scuba cylinder be visually inspected at least every 2.5 years by a properly trained inspector. As part of this inspection, Luxfer further requires that the cylinder neck be tested with an eddy-current device such as Visual Plus™, Visual Plus 2™, Visual Plus 3™,Visual Eddy™ or equivalent non-destructive testing equipment. When properly used, eddy-current devices contribute significantly to early detection of difficult-to-observe sustained-load cracks in the necks of 6351-alloy cylinders. If the cylinder passes the inspection, the inspector will document that fact. If the cylinder fails the inspection, it must be removed from service immediately. Do not use Luxfer 6351-alloy scuba cylinders that have not been both visually inspected and eddy-current tested and then properly documented.

This Luxfer-required visual and eddy-current inspection is in addition to periodic requalifications (including retesting and inspections) required or recommended by various regulatory agencies around the world. The intervals between retests and inspections vary from country to country.

In addition to the required inspection and testing described above and in keeping with U.S. scuba industry standards, Luxfer recommends that all Luxfer 6351-alloy scuba cylinders be visually inspected at least once each year by a properly trained inspector.

For cylinders in heavy use (for example, those filled five or more times a week), Luxfer recommends visual inspection every four months. For more information, refer to Luxfer's Scuba Cylinder Inspection Guide, which is available by calling Luxfer at 800-764-0366 or by visiting the Luxfer web site at www.luxfercylinders.com.

Cylinders made from Luxfer's proprietary 6061 alloy are not susceptible to sustained-load cracks. Therefore, Luxfer does not recommend the use of earlier-generation eddy-current devices-e.g., Visual Plus, Visual Plus 2, and Visual Eddy-with Luxfer 6061-alloy cylinders because field experience has shown that using these devices can result in misleading "false-positive" readings and erroneously condemned cylinders.

However, Luxfer does approve the use of the Visual Plus 3™ eddy-current device with Luxfer 6061-alloy cylinders. After laboratory testing, Luxfer has determined that properly calibrated VisualPlus 3 equipment eliminates the "false positive" problem, accurately measures features in the neck area of aluminum cylinders, and generally provides correct pass or fail assessments with cylinders made from Luxfer's 6061 alloy. As of the date of this Luxfer Policy Statement, VisualPlus 3 is the only eddy-current testing device suitable for use with Luxfer 6061-alloy cylinders. (During a visual tank inspection (VTI) at Deep-Six, the VisualPlus 3 is used on all aluminum cylinders and a full report is produced for the owner.)

Luxfer emphasizes that the use of eddy-current devices to improve the quality and accuracy of inspections does not eliminate the need for a thorough visual inspection by a properly trained and qualified inspector.

In keeping with U.S. scuba industry standards, Luxfer recommends annual visual inspection of Luxfer 6061-alloy cylinders by a properly trained inspector. For cylinders in heavy use (for example, those filled five or more times a week), Luxfer recommends visual inspection every four months. These recommended inspections are in addition to periodic requalifications (including retesting and inspections) required or recommended by various regulatory agencies around the world. The intervals between retests and inspections vary from country to country.